INPHOTEC includes state-of-the-art facilities for both front end as well as back end processes, which are summarized below:

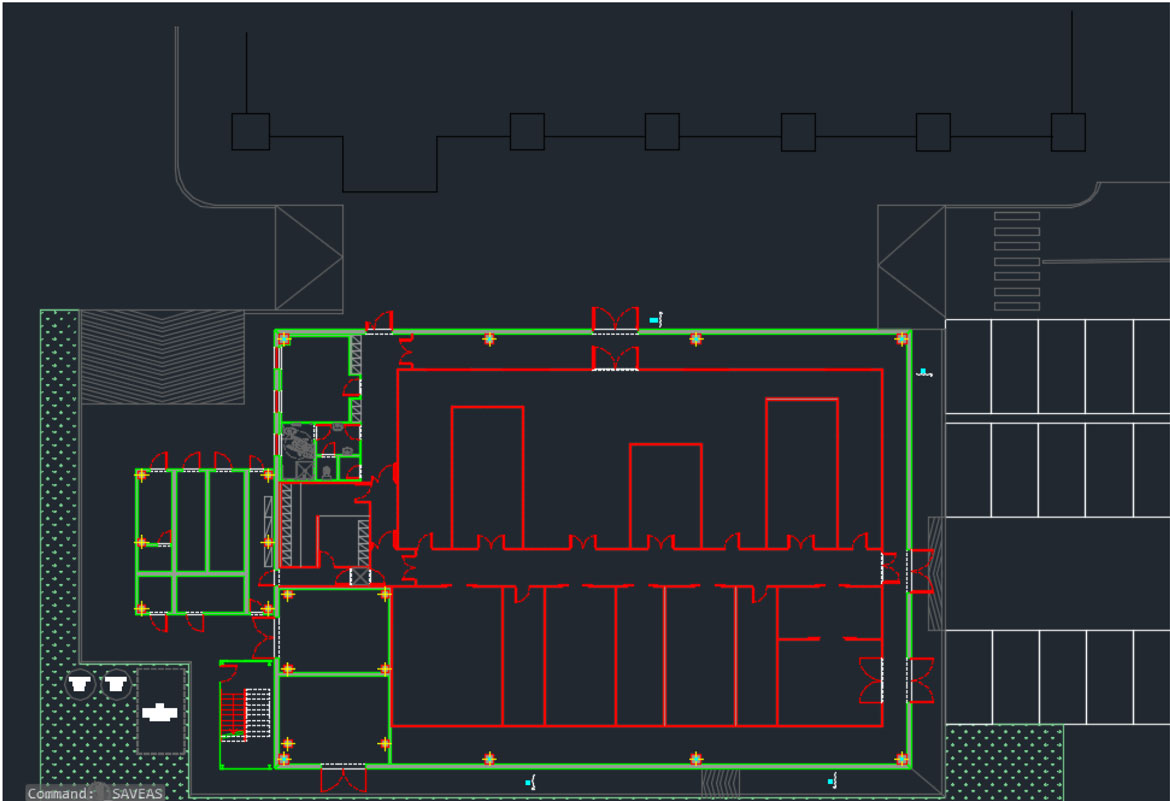

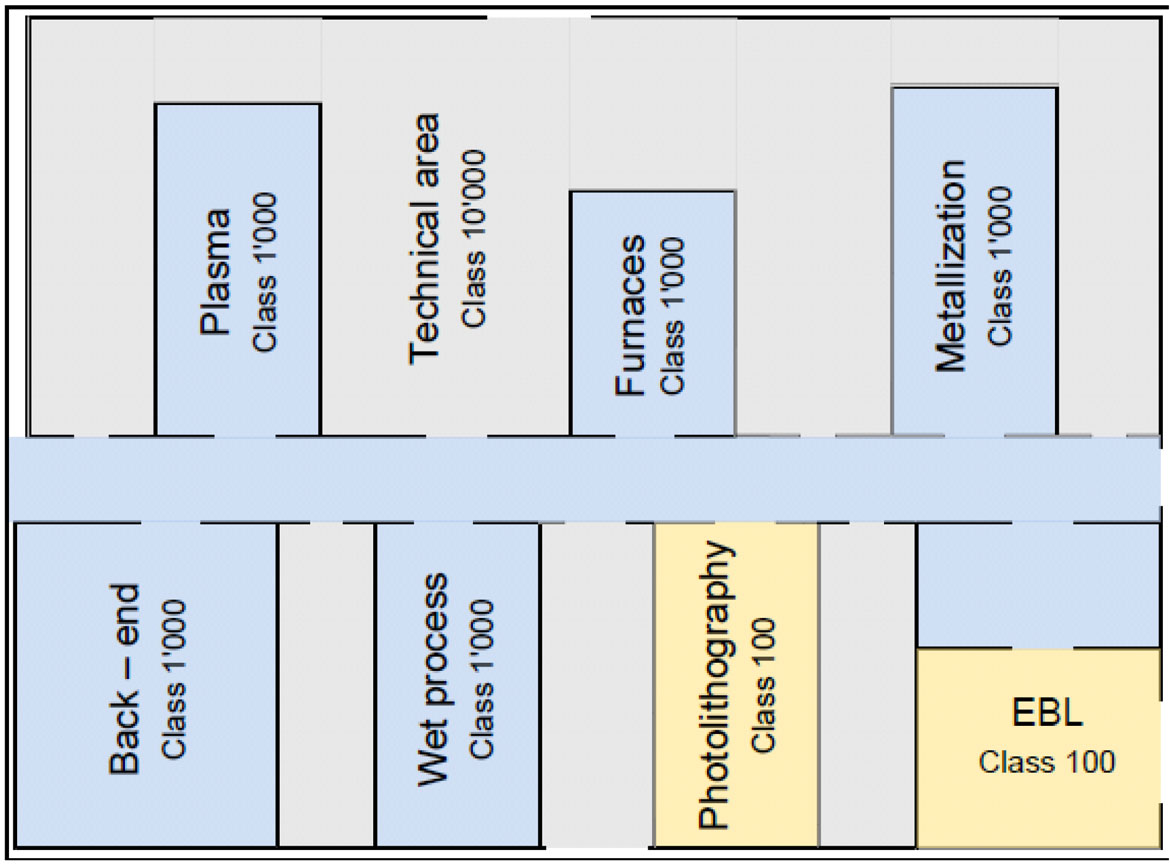

- 550-m2 clean room area, 150-m2 service area = 700-m2

- 40-m2 class 100 ISO5, 190-m2 class 1000 ISO6, 320-m2 class 10000 ISO7

- Gas “Electronic Grade”: nitrogen, Ar, SF6, CH2F2, C4F8, CF4, CHF3, O2, N2O, NH3, SiH2Cl2, GeH4, SiH4, H2

- Gas Abatement Emergency System (chemical absorption)

- Deionized Water Centralized System: 4m3/hour SEMI standard ASTM 5127-07

The centre makes available six different technological platforms.

The key equipment includes:

- Lithography equipment used for the high precision definition of patterns and structures on wafer, done with Electron Beam VECTOR HB6 HR and Karl SUSS MA6 BA6

- Etching equipment including plasma dry etching and wet etching done with OMEGA MORI SPTS and TMAH REACTOR

- Dielectric material and metal deposition performed using STS MAC, OXFORD PLUS PRO 100, SEMCO system and VTR 7000 for dielectric, and TEMESCAL BCD 2800 for metal deposition

- Metrology equipment used for the physical characterization of deposited materials as well as devices realized at INPHOTEC, performed using FILMTEK 4000E-IR and TESCAN MIRA 3 XMH

- Packaging equipment for the realization of prototypes and products, including a FINETECH automatic die-attachment machine, and automatic and a manual wire-bonder, a submicron precision flip-chip machine, an automated alignment bench for optical pigtailing.